I have been having a really tough time trying to accomplish a seemingly simple task. I want to create a sign that is made up completely of text, a particular font.

Mar 12, 2009 - I tried unsuccessfully to create the font in autocad and explode it then send it to lazy cam. While messing around with that I realized that I could. Aug 18, 2009 - TUTORIAL # 2 - MILLING A PROFILE A DIFFERENT WAY 53. LazyCam is a beta-release free importer included with Mach3.

I tried unsuccessfully to create the font in autocad and explode it then send it to lazy cam. While messing around with that I realized that I could actually create the text in Lazycam. That worked except once in Mach3, the mill moved so slow that you could not even see it move. It took all night to trace a single letter.

At the top of the Gcode it says Default Foam Post. Not sure what that means or if thats the problem. Jason Similar Threads: • Problem- • • Need Help!- •.

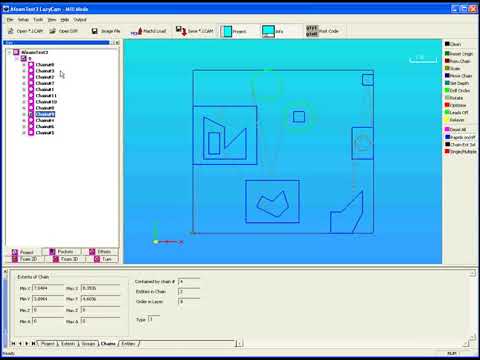

As I said in my first post about my little CNC mill I am currently using the trial version of Mach3 to control the machine. Included along with Mach3 is a trial version of LazyCam which will (supposedly) convert DXF files into G-code after you input the tool info, offsets etc.

There are no instructions with Lcam but there are tutorial videos. I actually purchased a disk with all of the videos and current programs so I could watch them when not connected to the internet. I have watched everything 2 or 3 times and felt fairly comfortable, I thought.

My first real project came up. I drew the items up in Autocad 2002, sent everything to a single layer and saved it as an Acad R12 DXF. (Come to find out later that a 3rd party freeware file is actually needed to convert the acad dwg file into DXF or Lcam wont load it.

Skymap pro 11 crack download 1. Another story) So I load the dxf into Lcam, arrainge my tool paths and offsets and everything looks pretty good. I click on the 'post g-code' button, the text at the bottom says it did but I get nothing.

Even with it set to automatically load G-code into mach3, nothing. What am I missing? Finally after several hours I gave up and wrote the g-code manually by typing it into notepad.

I guess I can't really complain because it is a free trial version, but what good is a CAM program that won't post? I hear this all the time.and we see it with DXF files provided to us by customers when they 'won't machine' because the code is bogus.so OUR software is bad.when in reality. You might want to check the concurrency of your DXF elements in the DXF file. If the endpoints of the lines / arcs don't actually 'meet' some of these CAM products won't create a path. This means digging into the DXF file and line by line checking the actual coordinates of the end points that are SUPPOSED to meet. Looking at them on the screen isn't accurate enough. Game 7 sins untuk android full. Remember, you machine tool works to 0.001' or 0.0001' while a plotter / printer only cares about what it LOOKS LIKE.and if the end points don't exactly match, doesn't care a hoot.